What are metal shredder parts?

Metal shredder wear parts are essential components of metal shredding machines, designed to withstand the harsh conditions encountered during the shredding process. These parts play a critical role in ensuring the efficient and continuous operation of metal shredders, which are industrial machines used to reduce the size of metal scrap for recycling or disposal purposes.

Metal shredder parts are subject to extreme forces and abrasion as they come into contact with the shredded metal materials. Therefore, they must be made from high-quality materials with excellent wear resistance, toughness, and durability.

The common metal shredder parts include:

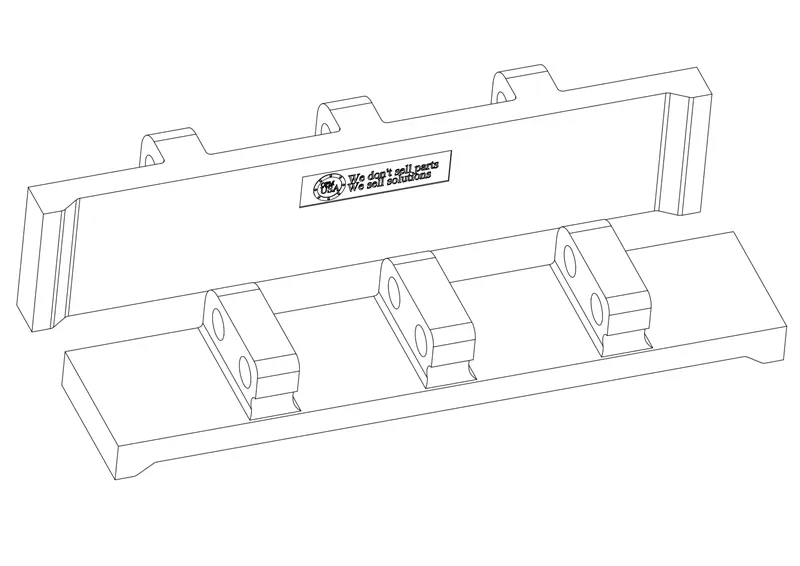

- Shredder hammers. Hammers are designed to impact and break down metal scrap, facilitating shredding. Like shredder blades, hammers must be made from durable materials to withstand the repetitive impact forces encountered during shredding.

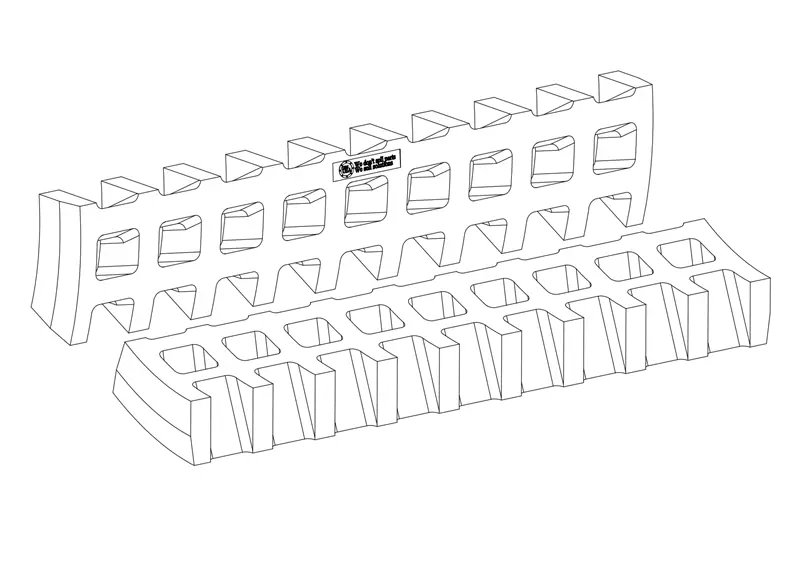

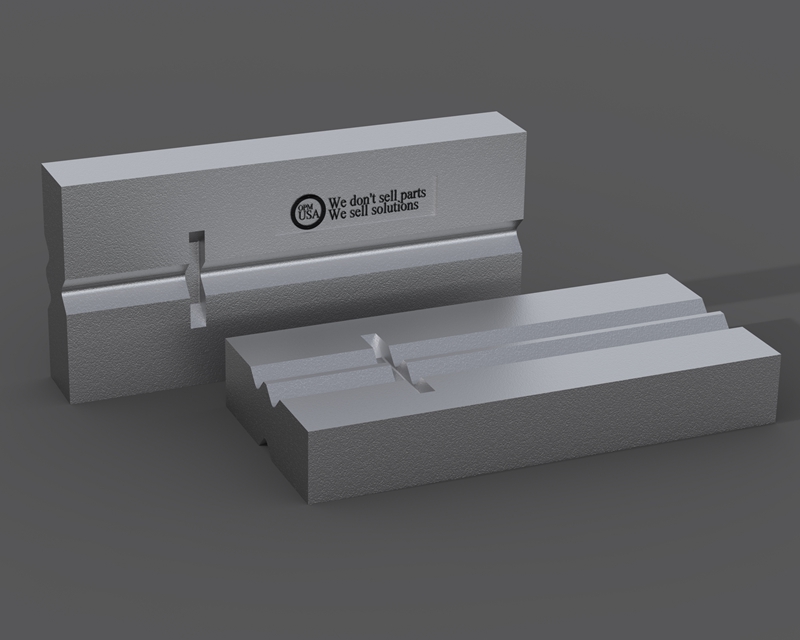

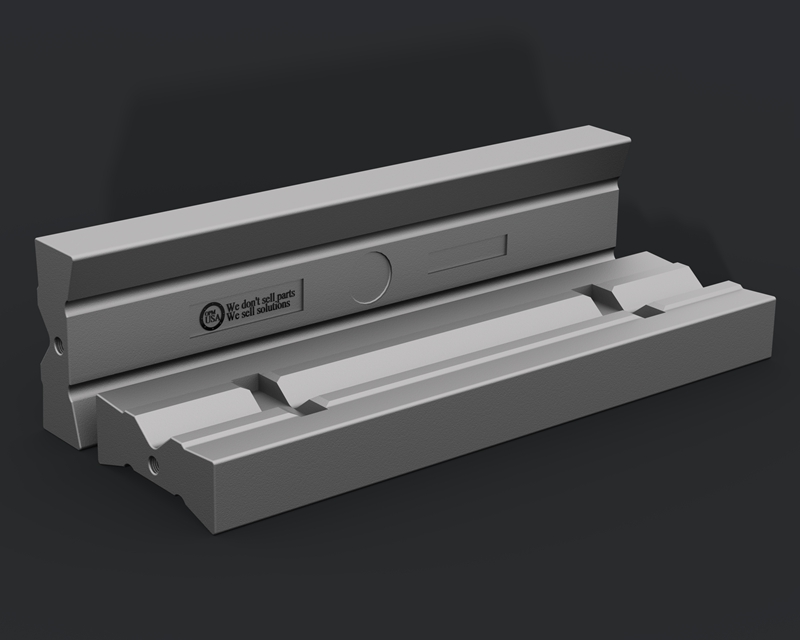

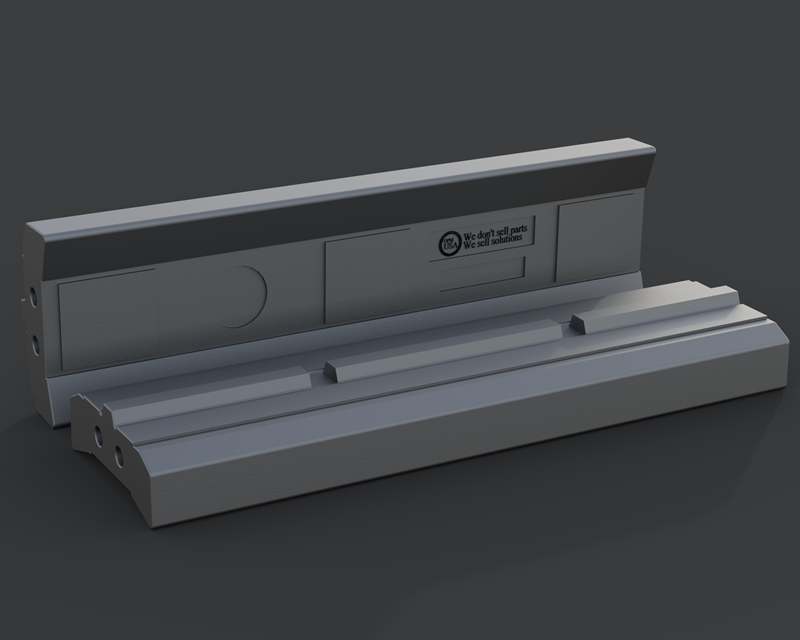

- Shredder grates or screens. Grates or screens are also crucial wear parts in metal shredders. These parts help control the size of the shredded material and prevent oversized pieces from passing through the shredder. Grates are typically made from hardened steel or other wear-resistant materials to withstand the abrasive action of metal scrap.

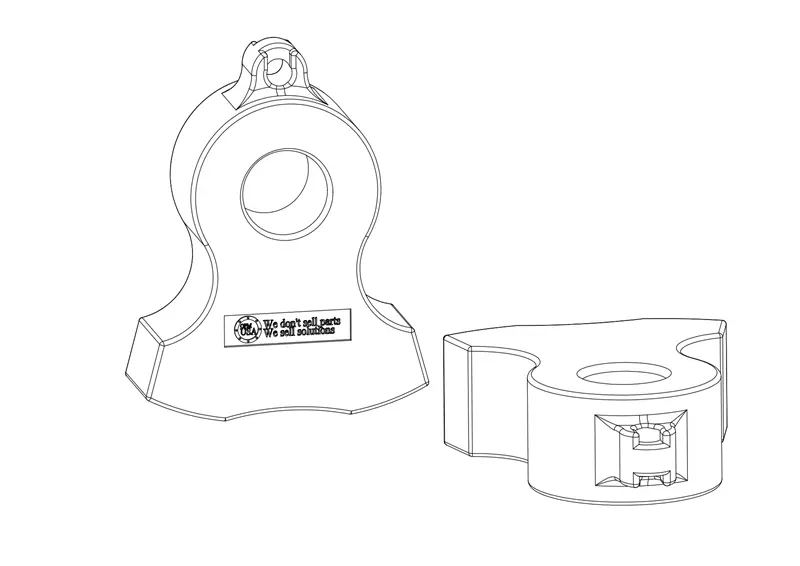

- Shredder caps. Rotor caps are another important wear part in metal shredders. These caps cover the ends of the shredder rotor and direct the material flow within the shredder. Rotor caps must be made from durable materials to withstand the forces encountered during shredding.

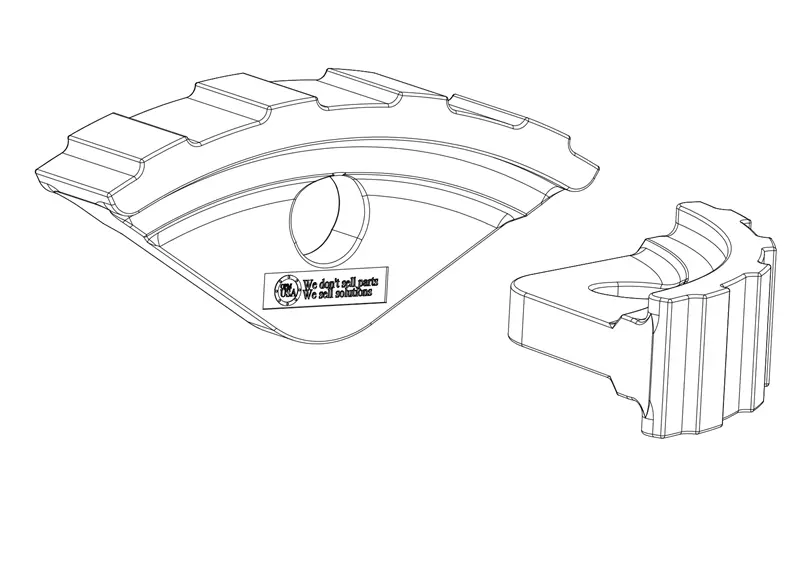

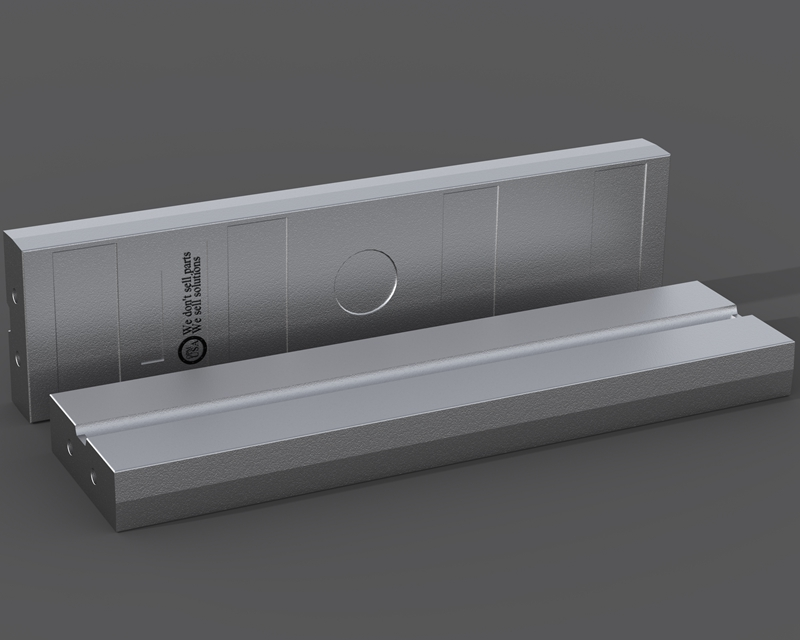

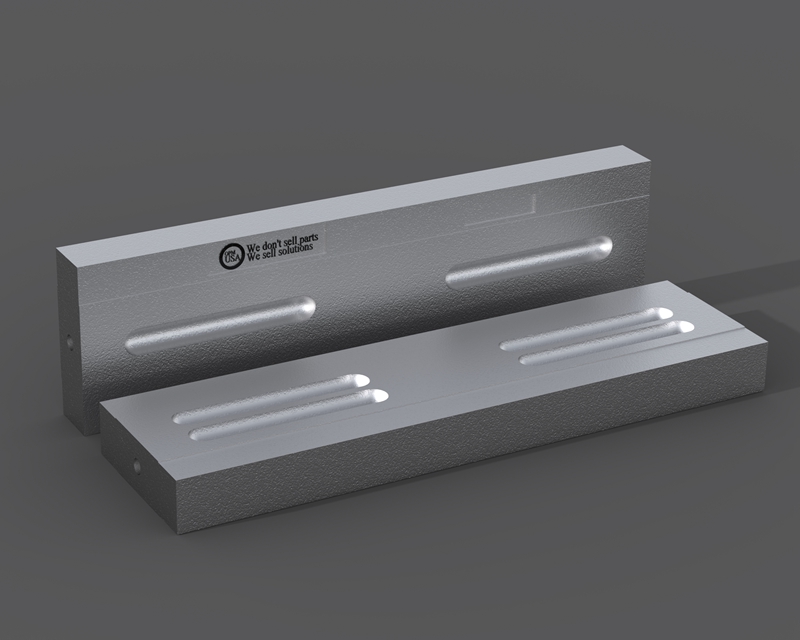

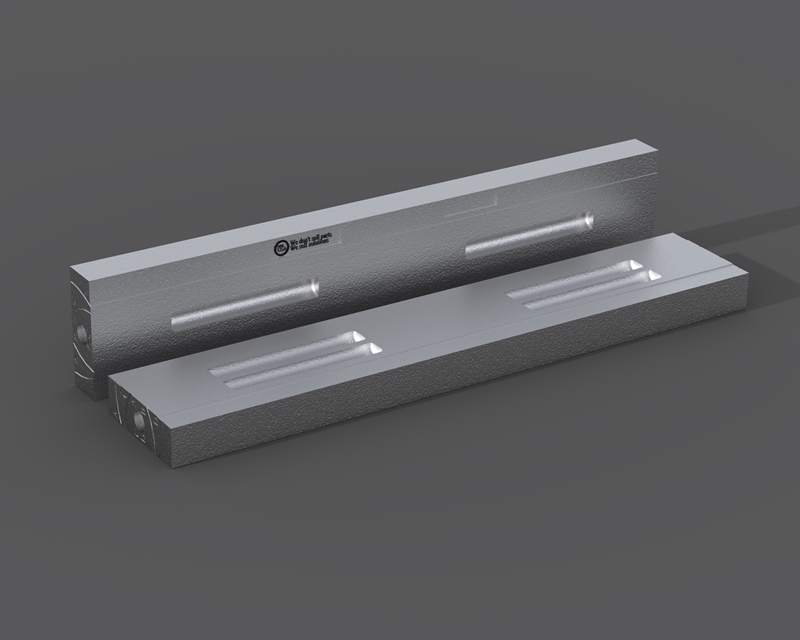

- Shredder wear plates. Other metal shredder wear parts include wear plates, which protect the interior surfaces of the shredder from abrasion, and breaker bars, which help break up larger pieces of metal scrap.

Regular maintenance and replacement of metal shredder wear parts are essential to ensure the continued efficiency and reliability of the shredder. Over time, worn parts can become worn or damaged, reducing shredder performance and increased downtime. By using high-quality wear parts and implementing a proactive maintenance schedule, operators can maximize the lifespan of their metal shredders and optimize shredding performance.