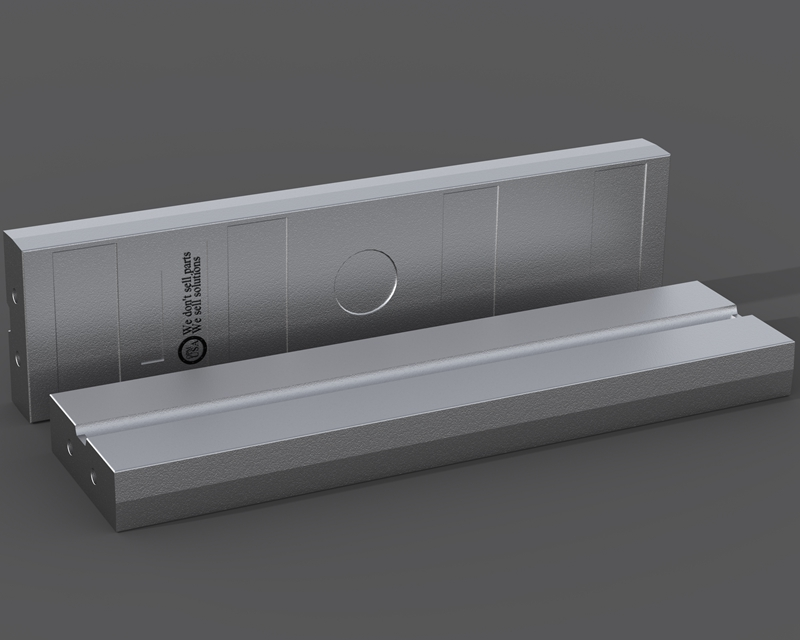

What are metal shredder wear liners?

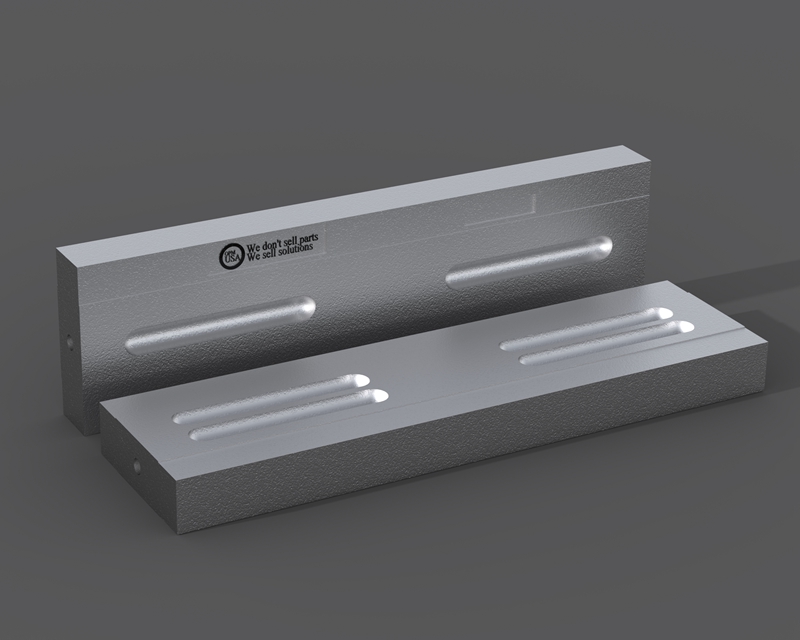

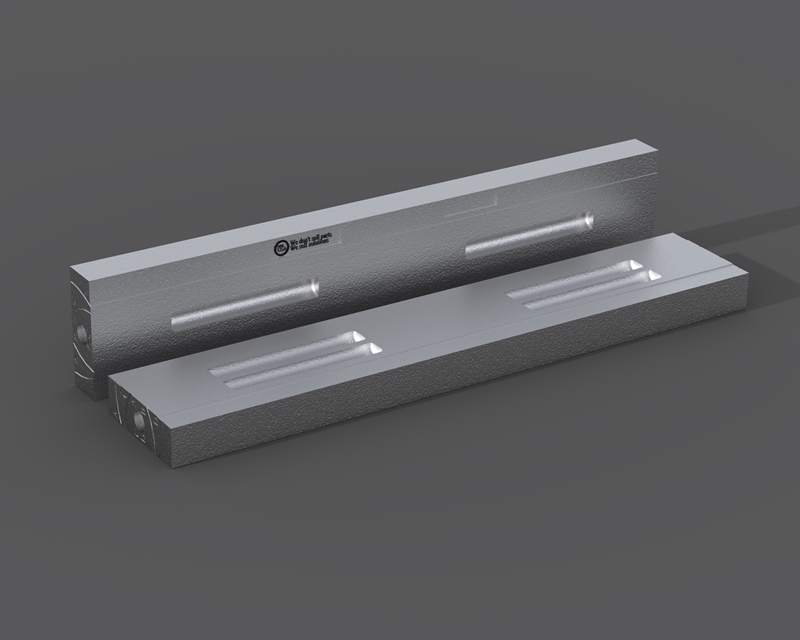

Metal shredder wear liners are protective components installed inside industrial shredding machines, particularly in metal shredders. These liners are typically made from durable materials such as abrasion-resistant steel or alloy steel, and they line the interior surfaces of the shredder’s cutting chamber.

The functions of metal shredder wear liners include:

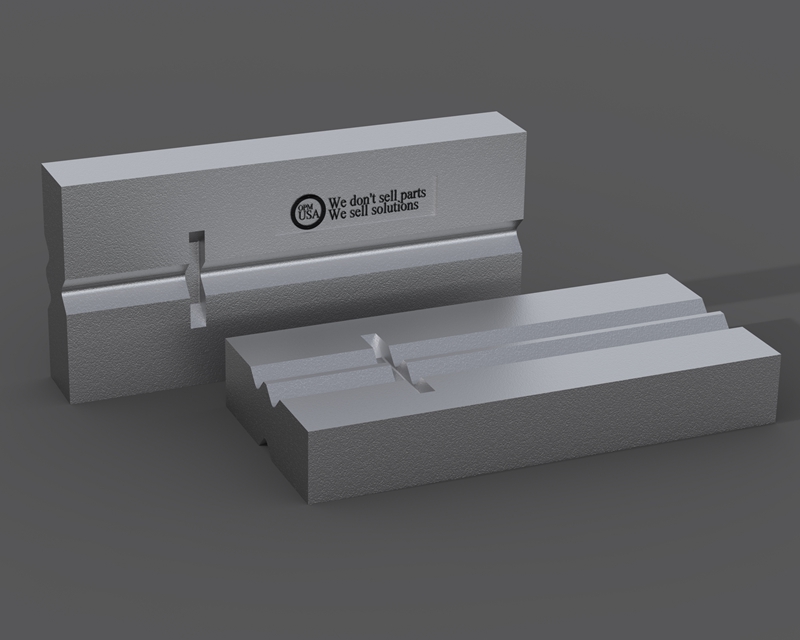

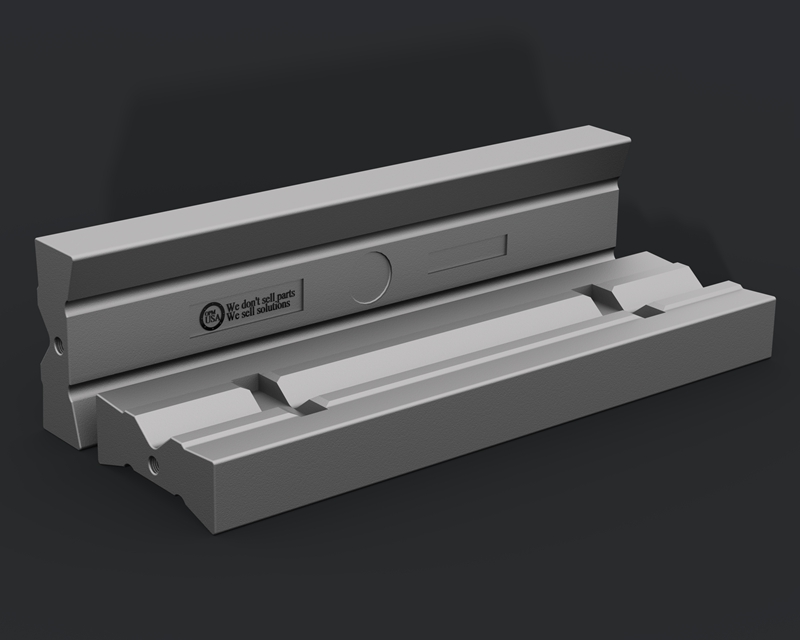

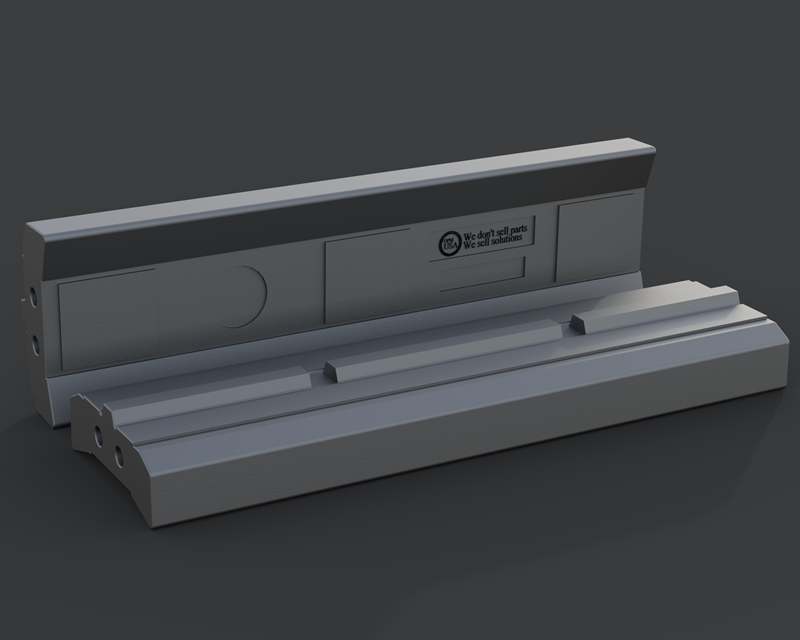

- Abrasion Resistance: Metal shredder wear liners protect the inner surfaces of the shredder from abrasive wear caused by the continuous shredding of metal objects. This helps prolong the shredder’s lifespan and reduce the frequency of maintenance and replacement.

- Impact Resistance: Besides abrasion, wear liners protect against high-impact forces generated during the shredding process. They absorb the impact energy and prevent damage to the shredder’s components, ensuring smooth and efficient operation.

- Material Containment: Wear liners help to contain the shredded material within the cutting chamber, preventing spillage and ensuring efficient material processing. This containment reduces the risk of material buildup and blockages, maintaining the shredder’s performance and productivity.

- Noise Reduction: Metal shredder wear liners can also help to dampen the noise generated during the shredding process, creating a quieter working environment in the facility.

- Improved Safety: By reducing wear and tear on the shredder’s internal components, wear liners contribute to a safer working environment for operators and maintenance personnel.