What are Impact Plates?

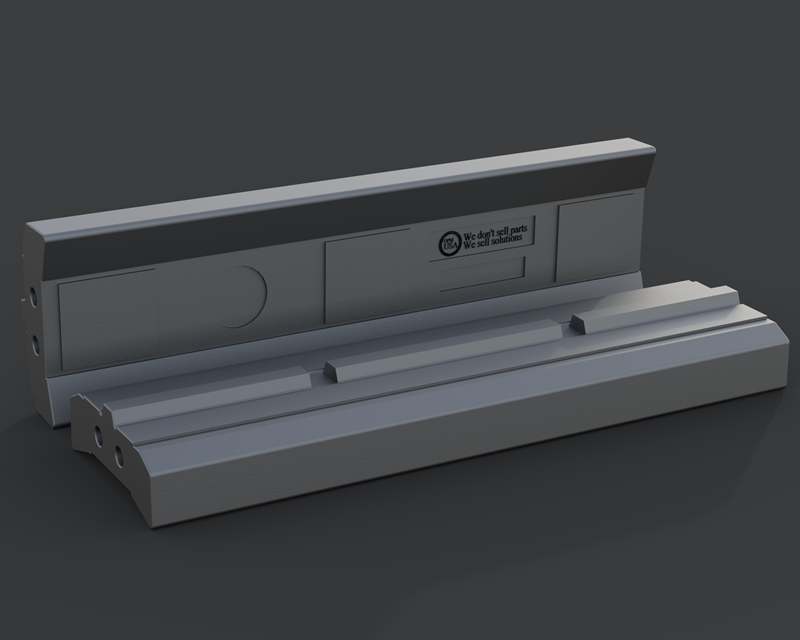

Impact plates are the central wear-and-tear part of the crusher. Impact plates are usually made of high-strength steel and come in different shapes. They are designed to tolerate high impact and crushing pressure. The plates are mounted on the impact bars that come fixed to the rotor and are supplied in different shapes, which can be adjusted to the client’s customization request.

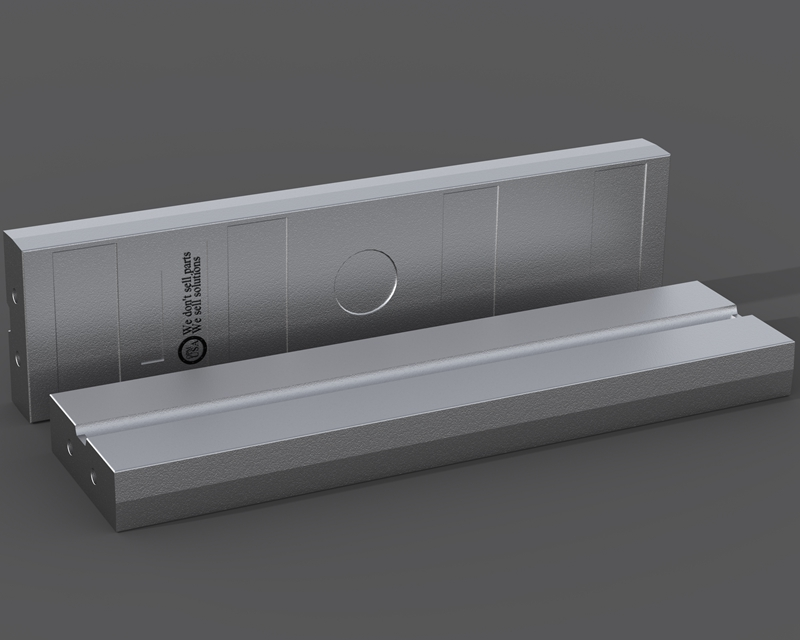

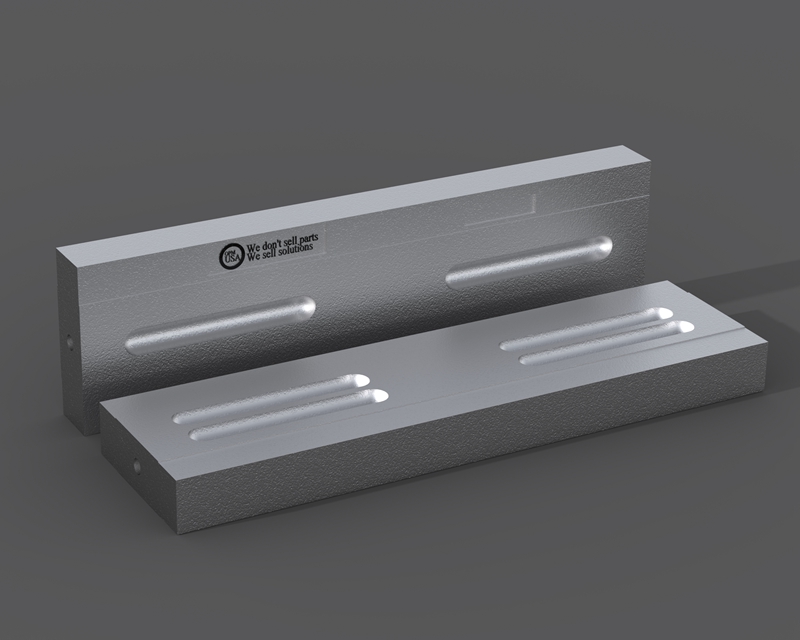

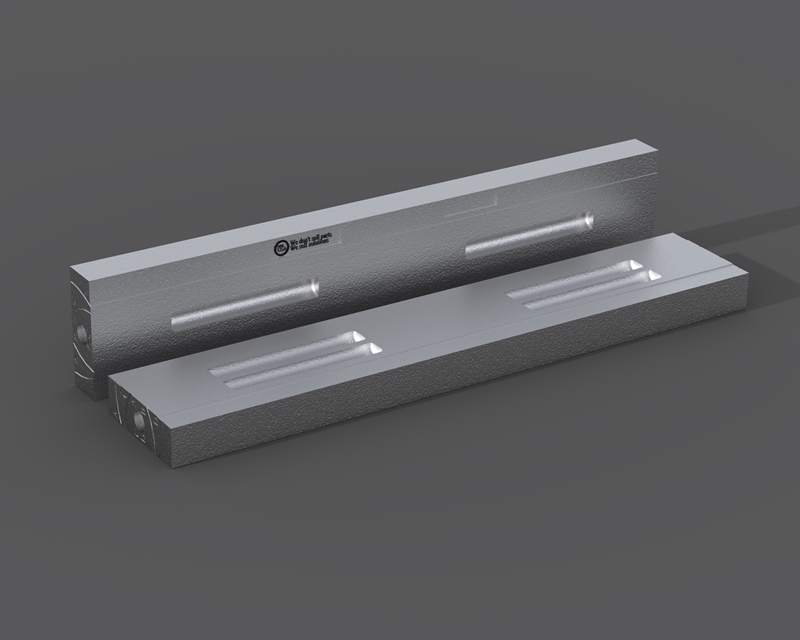

Some of the most common impact plate shapes are rectangular and wedged shape plates.

The primary function of an impact plate is to reduce the impact of the crushing of raw materials. When the material is shot from the blow bar, the crushed raw materials are rebounded back to the crushing area for a second crushing.

Material Of Impact Plates

The impact plate is the main wear part that protects the impact crusher. Generally, we adopt high manganese steel to make impact plates. However, their service lives are relatively short.

Many clients, however, look to improve abrasive resistance. Some manufacturers use abrasive-resistant plastic or cobblestone to protect and improve the service life of the plate.

| Material | Hardness | Application |

| Manganese Steel | 200-250HB | Large feed size low abrasiveness stones |

| Martensitic steel | 500-550HB | Large to medium feed size low abrasiveness |

| Martensitic + Ceramic | 500-550HB | Small to medium feed size high abrasiveness |

| High chrome | 600-650HB | Small feed size high abrasiveness without unbreakable objects |

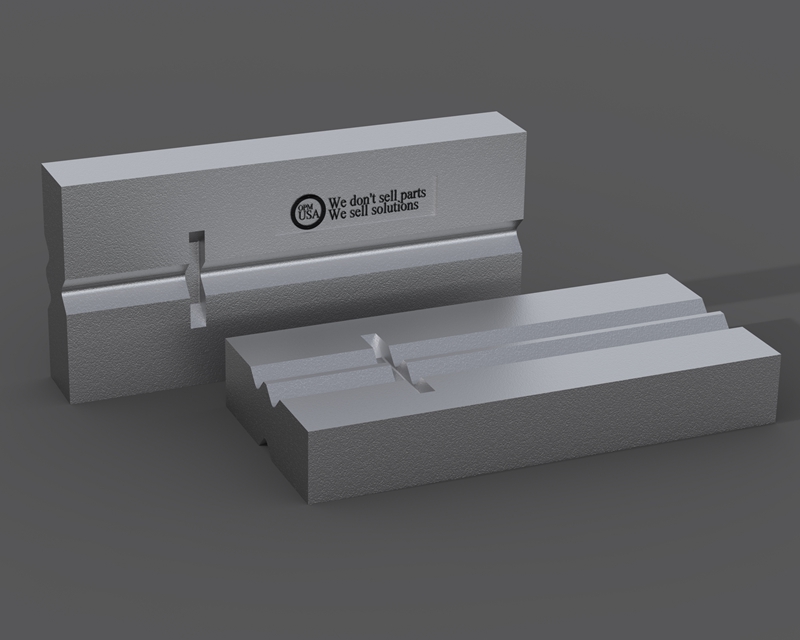

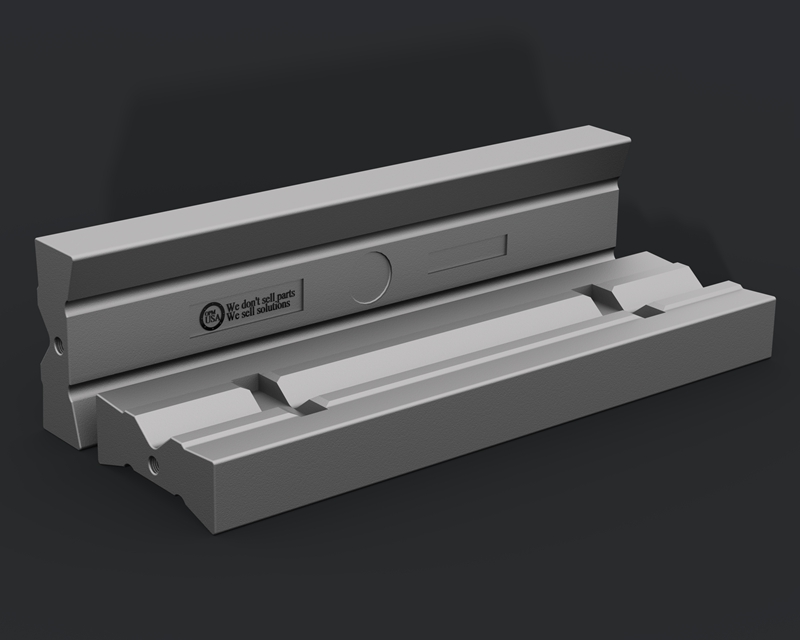

Shape Of Impact Plates

The shape of the impact plate plays a significant role in the crushing impact. There are many shapes designed to improve abrasive resistance. Our clients’ most popular impact plate shapes are circular, polyline, and arc. These shapes are most beneficial for multiple crusher experiences.

Circular-arc-shaped impact plate: This particular shape pushes the material to fall onto plates as they rush into each other in the center. The shape encourages more materials to be crushed into each other. A circular shape is one of the most preferred and efficient crushing shapes for highly abrasive materials.

Polyline-shaped impact plate: in this shape, the material impacts with the plates vertically, immediately crushing the material. The vertical shape does not imemdiately crush other materials, so there is sliding between crushing materials. This shape is best suited for more extensive materials. However, polyline shaping takes more time.

The circular-arc-shaped impact plate offers better crushing efficiency than the polyline-shaped impact plate.