What are metal shredder hammers?

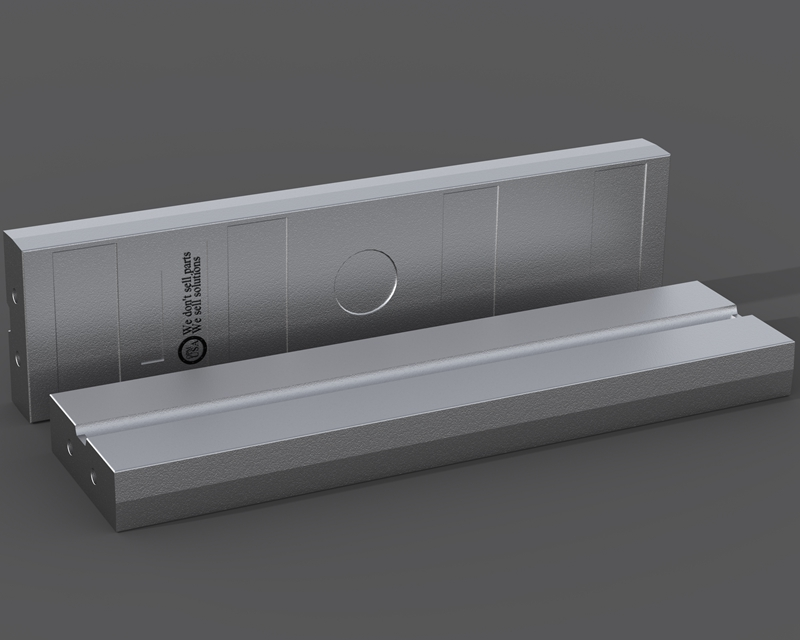

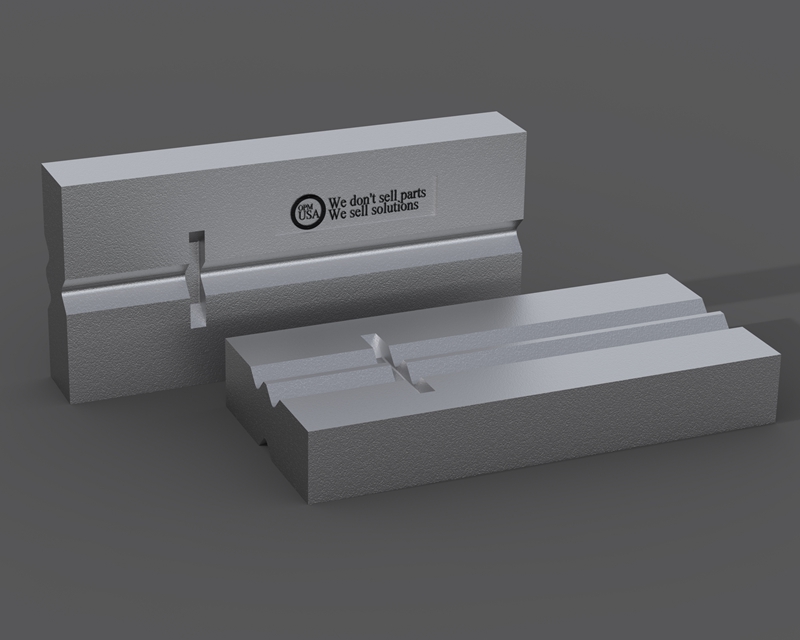

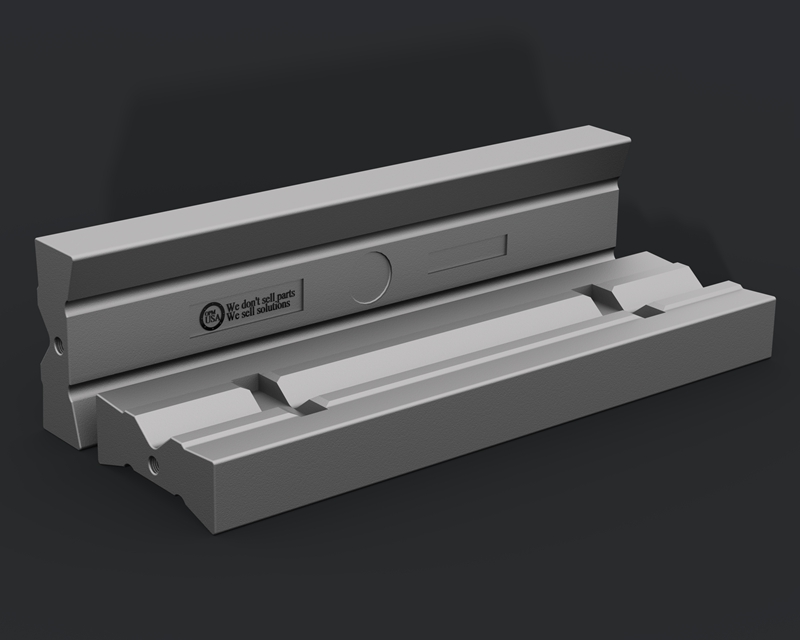

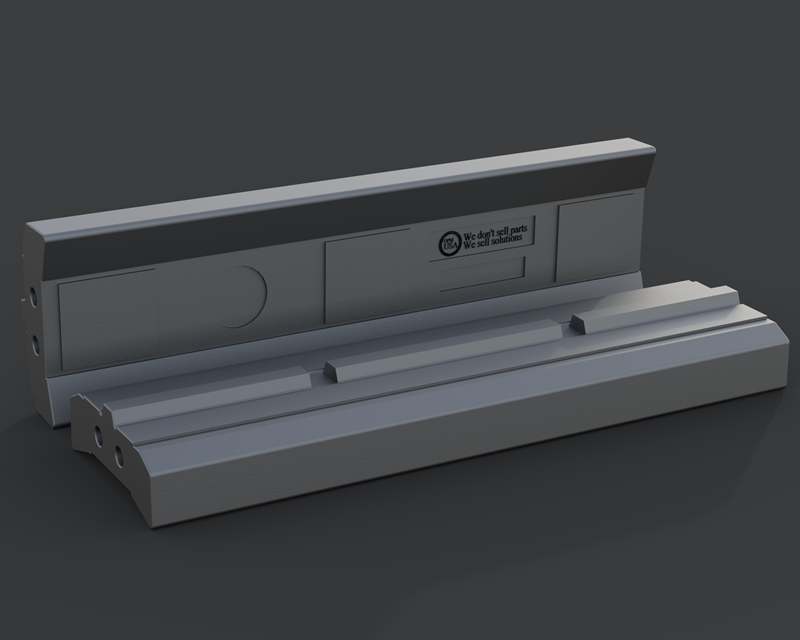

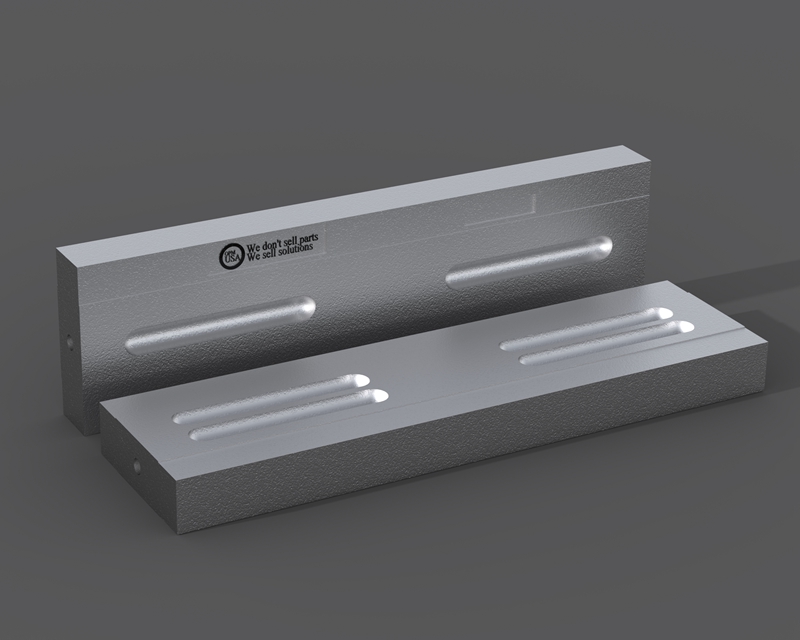

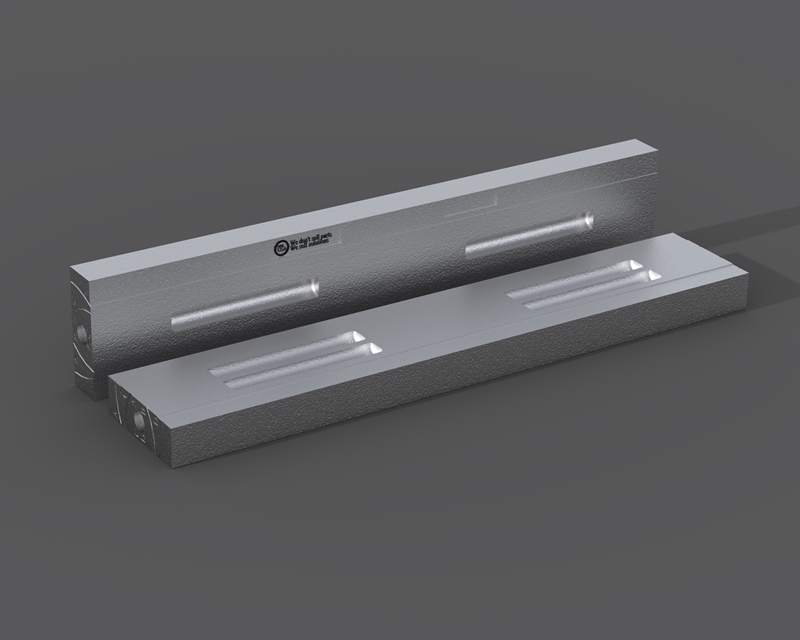

Metal Shredder Hammers are specialized tools used in industrial machinery, particularly in shredders designed to break down metal objects into smaller pieces or particles.

These hammers are typically made of high-strength materials like hardened steel and are engineered with specific shapes and configurations to shred and pulverize metal materials effectively.

They play a critical role in the metal recycling and processing industry, enabling efficient and cost-effective disposal or repurposing of metal waste.

Material of Metal Shredder Hammers

The material selection for metal shredder hammers is crucial to ensure durability, strength, and resistance to wear and tear. Common materials used for manufacturing metal shredder hammers include:

- High Carbon Steel: Known for its hardness and toughness, it is a popular choice for shredder hammers due to its ability to withstand heavy impact and abrasion.

- Alloy Steel: Alloy steel contains additional alloying elements such as chromium, molybdenum, or nickel, which enhance its mechanical properties, including hardness, toughness, and wear resistance. This makes it well-suited for demanding shredding applications.

- Tool Steel: Tool steels are specially designed for cutting and shaping tools, offering high hardness, wear resistance, and toughness. They are often used for shredder hammers to maintain sharp edges and withstand repetitive impact.

- Manganese Steel: Manganese steel, known as Hadfield steel, is renowned for its exceptional toughness and work-hardening ability. It is commonly used in high-impact resistance applications, making it suitable for shredder hammers subjected to heavy loads and abrasive materials.

- Carbide Inserts: Some shredder hammers feature carbide inserts or tips made of cemented carbide materials. Carbide inserts provide superior wear resistance and can withstand extreme conditions, extending the service life of shredder hammers in challenging environments.

The specific material selection depends on factors such as the type of metal being shredded, the operating conditions of the shredder, and the desired performance characteristics, such as hardness, toughness, and wear resistance.