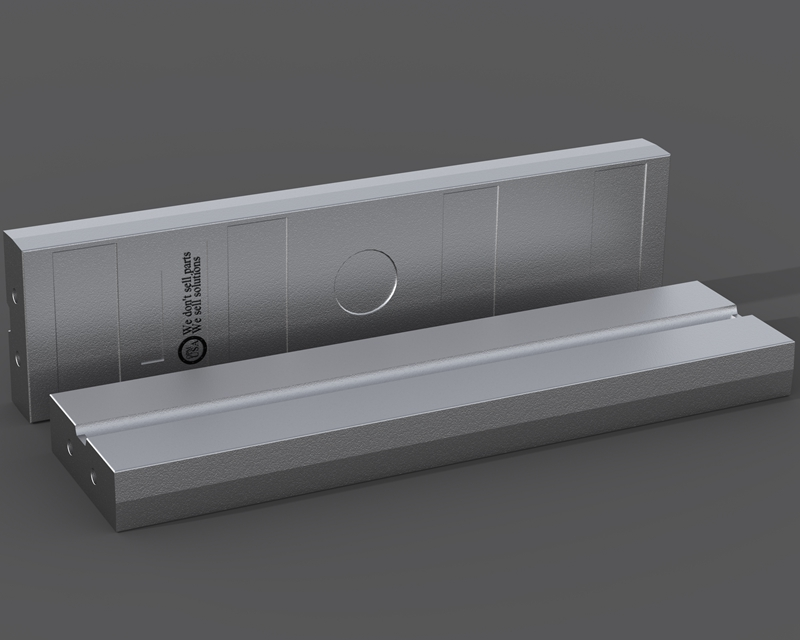

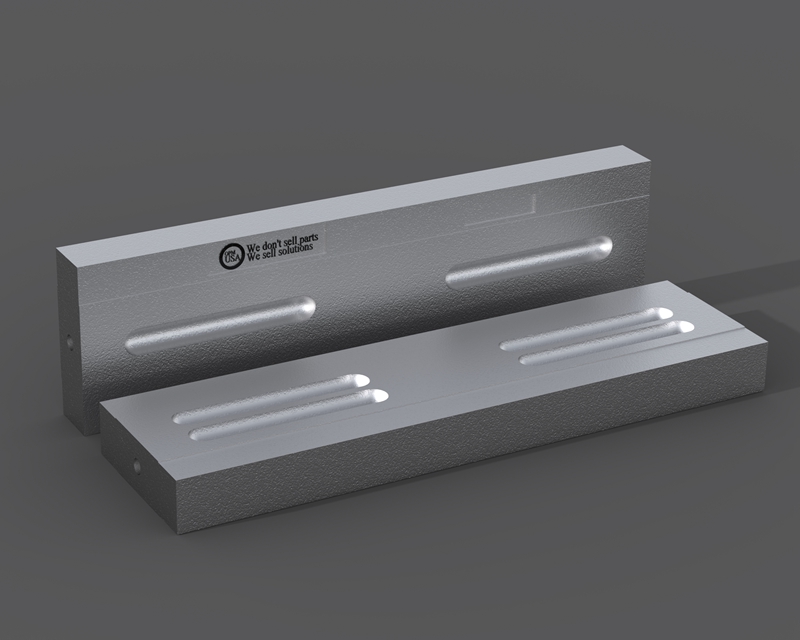

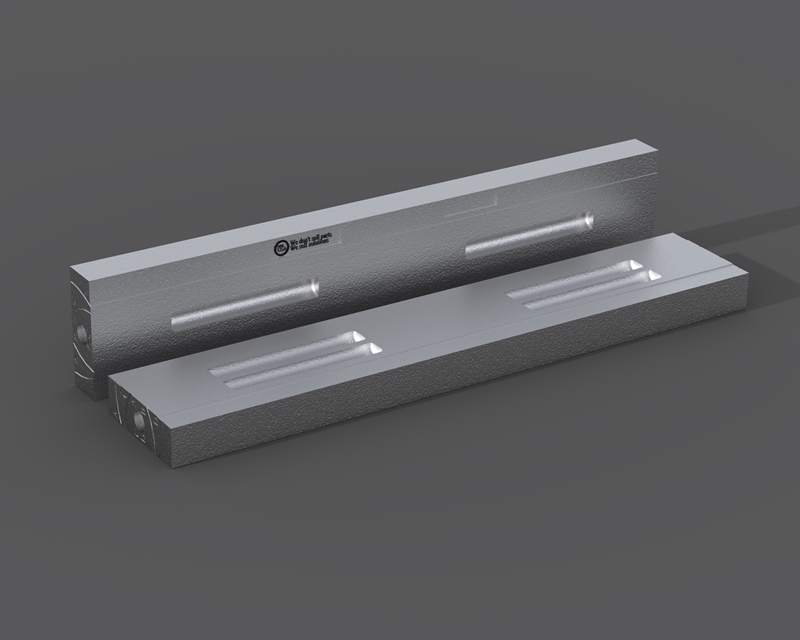

What are metal shredder caps?

Shredder caps, also known as shredder hammer caps or hammer tips, are protective components attached to the working ends of shredder hammers in industrial shredding machines. These caps serve several important functions:

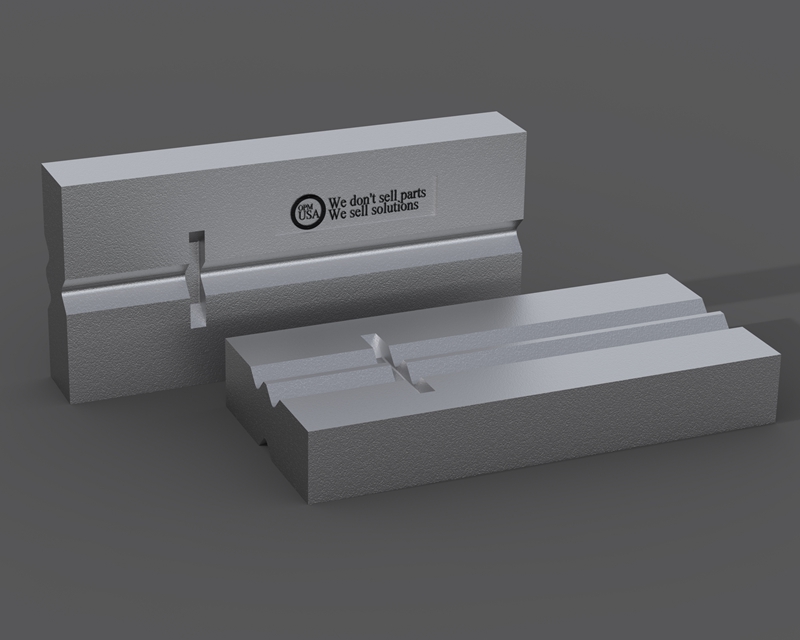

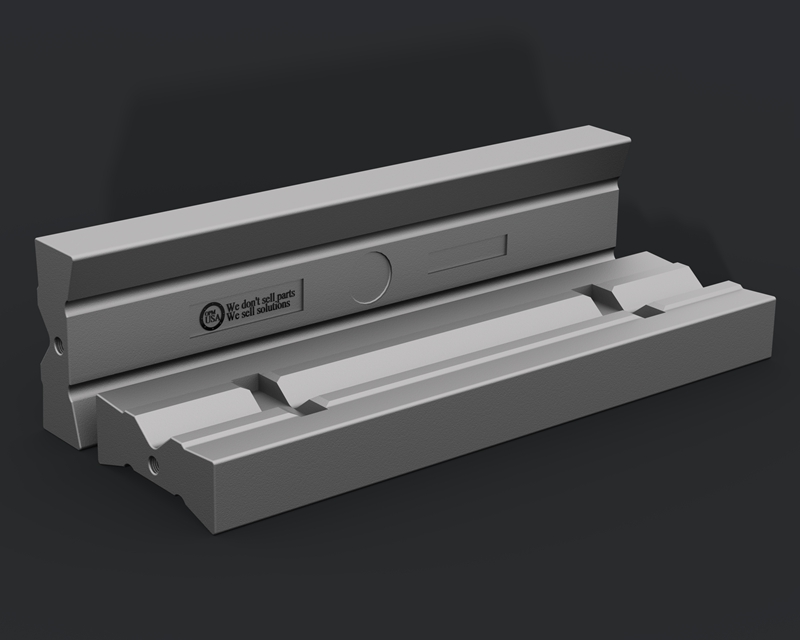

- Wear Protection: Shredder caps act as sacrificial wear components, protecting the hammer’s working surface from direct contact with shredded material. They absorb the brunt of the impact and abrasion, extending the service life of the hammers and reducing the need for frequent replacements.

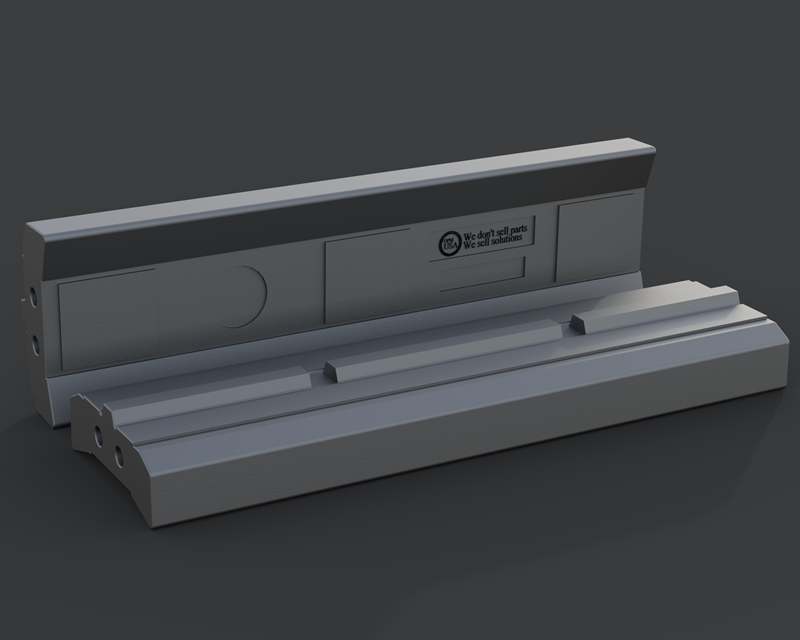

- Enhanced Performance: By shielding the hammer’s critical wear areas, shredder caps help maintain the hammer’s effectiveness and efficiency in breaking down materials. They ensure consistent performance over time, allowing the shredder to maintain its throughput and productivity levels.

- Material Quality: Shredder caps are typically made from high-quality, abrasion-resistant materials such as alloy steel, manganese steel, or carbide inserts. These materials are chosen for their durability and ability to withstand the harsh operating conditions of shredding, including impacts from hard and abrasive materials.

- Cost Savings: By prolonging the service life of shredder hammers, shredder caps help reduce maintenance costs associated with hammer replacements and downtime for machinery repair. They contribute to overall cost savings and improved operational efficiency for shredding facilities.